Taking inventory is a critical step in optimizing your processes, especially when you have a clear understanding of your « why » and « who. » It involves assessing the resources at your disposal, the core systems already in place, and the applications currently in use.

Whether you’re starting from scratch or looking to improve on existing investments, a thorough inventory helps you avoid reinventing the wheel, maximize your existing assets, and make informed decisions for process enhancement.

With your “why” and “who” clearly in mind, it’s time to start taking inventory.

- What resources are available to you?

- What core systems and solutions are already in use?

- What applications are people already using?

Naturally, the answers to those questions will depend on where you are in your process maturity journey. If your company is in the very earliest stages of process improvement, there might be very little to work with in terms of existing resources and systems. Or perhaps your company has already invested a great deal, but the results have been subpar.

Avoid Reinventing the Wheel

Part of the importance of taking inventory is ensuring that you aren’t reinventing the wheel. If there are existing resources and systems, there are good reasons for trying to find ways to use them.

Firstly, it may simply be a waste of time and energy to replace existing systems. If the company already has business intelligence tools, it’s often more efficient to leverage them, or their data, to inform your process intelligence efforts.

The second reason to think carefully about how you work with existing systems is that trying to replace them may cause friction. In many cases, those systems are someone’s “baby.” That may mean a project that they’ve championed through the years, or even a career-defining choice that they implemented based on the best available information at the time. You’re not going to get very far by calling their baby ugly. Or telling them they need a new one!

Taking Inventory of Existing Technology

With the above in mind, a good starting point for taking inventory is to take stock of existing process tools – especially ones actively used across the company. Examples might be:

- Diagramming tools like Visio or Lucidchart,

- Robotic Process Automation (RPA),

- Low-code Application Platforms (LCAPs),

- Business Intelligence (BI) tools, and

- Core systems: GRC, CRM, ERP, ITSM, etc.

If your company is already using some of these tools extensively, common objections you might hear from others are: “But we already have Business Intelligence. Why do we need this?” Or: “We already have RPA and a diagramming tool.”

A key point to remember is that having a collection of process tools is not the same as having a full process intelligence solution.

True process intelligence allows the business to optimize processes end-to-end, build the ideal versions of processes, and address the core pain points of cost, compliance, and efficiency.

Additionally, process intelligence adds value to the tools that are already there. For example, if the business is already spending money on RPA, it’s worth emphasizing that process intelligence can boost the performance and value RPA delivers. On its own, automation simply makes processes faster. But if there are underlying issues in the process, this may just be throwing gasoline on the fire! Process intelligence grounds automation by making it smarter, without the business needing to spend more money on RPA.. And the resulting value add makes it easier to garner support from the people most invested in the RPA tool.

Another common example is the conversion of static business process diagrams into live process models that can be used by other systems. Many existing diagramming tools don’t conform to Business Process Modeling Notation (BPMN) standards, meaning their outputs can’t be easily translated into the standardized format needed to use them in process optimization initiatives.

A good process intelligence tool can solve that problem by converting process diagrams into a BPMN structure. This allows the business to use its existing information to further process optimization efforts. It also adds an extra utility layer for stakeholders already invested in creating useful process diagrams.

Taking Inventory of Human Capital

The second consideration when taking inventory is the people in, and associated with, your company that hold the relevant knowledge to move a project forward. We’ve already touched on process and tech “owners” above – the individuals and teams already invested in specific aspects of process or process tools. Less obvious sources of process knowledge and support include:

Seasoned team members: These are people that have been with the company a long time, are deeply familiar with its process landscape, and can, therefore, provide invaluable domain expertise. This is especially important in cases where processes, or parts of processes, are siloed in different teams. The people who have been on those teams the longest are the perfect collaborators to get you started with understanding their processes.

Company consultants: Another great source of information and advice is consultants who already have extensive domain knowledge and know the frameworks you’ll be working with inside and out. Taking note of the projects with which those individuals are already involved, and positioning yourself as an ally, can be free visibility for your own efforts.

Innovation champions: Finally, note members of other teams that are coming up with bold new ideas and approaches. These are often people you can engage to support your own efforts. For example, if you know someone in marketing has almost convinced their team to use GenAI for generating advertisements, hop on their bandwagon and see if you can broaden the scope for some of your purposes.

An important point to remember when you start gathering information and working with different individuals across the company is to keep your approach principled and objective. This means trusting what people say, but also verifying it to ensure you’re getting all sides of the picture. Often, the way someone thinks a process works isn’t how it actually works. So, wherever possible, use data to validate your hypotheses about this.

Along the same lines, try to avoid making assumptions about the progress of others’ process optimization efforts. Instead, focus on thinking critically about their efforts so far. Do they have any data to show the progress they’ve made? And if they’ve hit roadblocks, think about how you can help to tear these down, while adding value to their efforts with process intelligence.

As you move through the inventory-taking process, it’s possible that the answers to some of the questions posed throughout this section are: “I don’t know.” That’s perfectly fine. The point is to be as transparent as possible about the information and resources you have available as you head into the next steps of your process optimization journey.

Ready to see how process optimization can transform your business? Book a demo today to explore how a comprehensive inventory can unlock new efficiencies and drive success.

Optimizing Your Process for Real-World Success

With your new and improved process designed, simulated and modeled, you’re finally ready to deploy it in real life. If everything goes well, it should run as intended, saving the company resources and time, and putting your optimization efforts on a few C-suite radars.

What many businesses fail to realize, however, is that, at this stage, the job still isn’t done. To ensure your process is running as intended, and that you haven’t overlooked anything during the other stages, there are a few additional capabilities and considerations to keep in mind.

Monitoring and Measuring Your Process

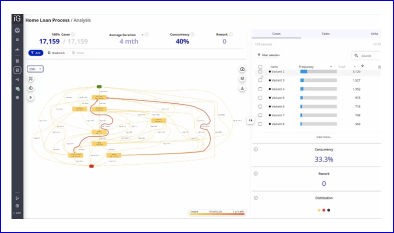

The first of these is the need for consistent process monitoring. Remember those metrics you defined during the early stages to quantify success for different stakeholders? The goal of process monitoring is to find out whether your process changes have reached the KPIs and results you outlined.

Adding a process monitoring tool to your process intelligence suite allows you to accurately measure the success of your process improvement initiatives and quantify how your new process runs.

Importantly, monitoring should be happening on an ongoing basis. A mistake many companies make is to run a new process over weeks or months before they take stock of how it’s performing. As a result, any negative trends or bottlenecks occurring in the new process go unnoticed until they become bigger problems.

This puts the company in a position of always reacting to problems at a delay, and can cause reputational, financial, and productivity risks.

There are also unforeseen risks and changes that are impossible to predict, which can all impact how a process performs over time. For example, a key employee leaving the business, diverted resources, or a botched system upgrade that creates a new bottleneck in the process.

What the company should be aiming for is to catch issues early. To do so requires monitoring processes in near-real time – that is, relevant metrics should be monitored and updated according to the frequency that makes sense for your business, whether that’s weekly, daily, or to-the-minute.

It’s also helpful to have key metrics displayed via a dashboard that can be easily accessed by all those involved in the process. This ensures everyone stays informed and can flag any risks or concerns specific to their team. It also allows you to respond to issues as they occur, and to quickly iterate on, and improve your process.

Augmentation and Integration

Another factor in optimizing your process landscape is whether the tools or solution you want to implement can be integrated with what you already have.

Choosing a process intelligence solution that can be easily integrated with popular systems, like LCAPs and automation, can make it much easier to get buy-in from others in the business, especially if you can add value to what they’re already doing.

Adding Analytics

A final capability that should be in every PEX professional’s process optimization toolbox is: predictive analytics.

Predictive analytics adds machine learning capabilities to process intelligence. This allows the business to learn from patterns in past data to identify potential issues before they occur and flag them so the process can be redirected.

For example, if a process is likely to follow a specific pathway that would result in an order being delayed, an algorithm trained on that process can create an alert before things go awry. Or it might identify a risk that could result in a process being non-compliant.

In other words, this is like having a crystal ball that empowers your business to make the right calls before things go wrong. This allows the business to shift its stance from reactive to proactive.

Creating a Continuous Improvement Environment

The beauty of a process intelligence approach is that it can be scaled up as needed. So, start with something simple, then expand and apply what you’ve learned to a bigger process or system. This allows you to test your ideas and then build your process landscape in a way that makes sense for your business.

What’s important is that you follow a systematic approach – one that prioritizes including relevant stakeholders and then discovering, designing, and optimizing your process in a way that adds value for everyone involved.

As you work, also keep in mind that processes aren’t static. No matter how well your process is running right now, over time your business environment will change. Your processes will need to be adapted and improved to maximize the benefits gained at every stage.

This idea of continuous improvement is at the heart of what true process intelligence has to offer. Using this approach, your business moves away from the idea that a process can be mapped and optimized in one sitting and then left to run the same way in perpetuity.

Instead, the continuous improvement enabled by process intelligence empowers the business to embrace a new paradigm, one that supports it to achieve long-term success by recognizing your process landscape for what it truly is: a living, breathing set of systems that must be adapted, improved, and reimagined in sync with the changing needs of your growing business.

Interested in learning more about how process intelligence can transform your business? Read through our whitepaper on process mining essentials, or book a demo to learn more about how iGrafx can benefit your organization.