“Veränderung ist die einzige Konstante im Leben.” Auch wenn der griechische Philosoph Heraklit nicht in der Lage war, zu verstehen, wie die Welt heute aussieht, hat diese Maxime den Test der Zeit überdauert. In der Geschäftswelt wissen Unternehmen, dass sie sich verändern müssen, um relevant zu bleiben. Neue Wettbewerber, technologische Durchbrüche, Talentmangel und die sich ständig weiterentwickelnden Kundenerwartungen zwingen Unternehmen zum Handeln.

Die Vorstandsetage hat die Mandate für die geschäftliche und digitale Transformation an die Führungsteams weitergegeben, die sie wiederum an die Mitarbeiter weitergegeben haben. Aber der Wandel findet nicht statt, zumindest nicht in dem erforderlichen Tempo.

Das Risiko von Prozessveränderungen

Was hält Unternehmen also zurück? Das Unbekannte natürlich. Bei all den positiven Aspekten, die Veränderungen mit sich bringen können, können sie unvorhersehbar sein, zu unbekannten Ergebnissen führen und im schlimmsten Fall das Unternehmen finanziell und rufschädigend kosten. Es gibt zu viele Variablen, um zu verstehen, was die Auswirkungen selbst einer geringfügigen Änderung sein könnten, und geschäftskritische Prozesse können sich keine Ausfallzeiten leisten. Selbst wenn jede Verbesserungsoption positiv wäre, welche bewegt die Nadel am meisten? Es gibt immer Opportunitätskosten.

Niemand kann die Zukunft vorhersagen, aber das bedeutet nicht, dass Sie keine fundierteren, datengesteuerten Entscheidungen treffen können. Wie gesagt, wir haben seit den antiken griechischen Philosophen einen langen Weg zurückgelegt. Hier kommt die Prozesssimulation ins Spiel.

Überwindung des Risikos

Im Kern nutzt die Prozesssimulation tatsächliche Prozessdaten, um Änderungshypothesen zu bestätigen, unvorhergesehene Konsequenzen aufzuzeigen und den Return on Investment zu quantifizieren. Es gibt mehrere Bereiche, in denen dies besonders nützlich ist.

Entscheidungsunterstützung

Wie bereits erwähnt, quantifiziert die Prozesssimulation die Auswirkungen einer Änderung in Bezug auf Effizienz, Kosten und Compliance. Es kann dazu beitragen, die strategische Entscheidungsfindung für ein Unternehmen zu unterstützen, indem es einen ROI (Return on Investment) für eine bestimmte Änderung bietet. Dies führt zu einer priorisierten Liste von Ideen zur Prozessverbesserung mit den damit verbundenen Kosten und Auswirkungen.

Es hilft bei der Beantwortung von Fragen wie:

- Wie hoch ist der Return on Investment beim Kauf dieser Maschine?

- Wie wirken sich meine Kosten aus, wenn ich ein nicht recycelbares Material gegen ein recycelbares austausche?

Was-wäre-wenn-Analyse

Im Gegensatz zur Entscheidungsunterstützung, die sich auf die Messung bekannter Ergebnisse konzentriert, geht es bei der Was-wäre-wenn-Analyse einfach darum, die Auswirkungen einer Änderung zu verstehen. Dinge wie neue Engpässe, die entstehen, oder unvorhergesehene Compliance-Überlegungen.

Es hilft bei der Beantwortung von Fragen wie:

- Welche Auswirkungen hat der Einsatz von KI-Agenten in unserem Callcenter auf die Kunden?

- Was passiert, wenn ich Personal umwidme, um es an den saisonalen Bedarf anzupassen?

Prognosen

Während sich die beiden vorherigen Verwendungen darauf konzentrierten, das Ergebnis einer Änderung zu verstehen, hilft Ihnen die Vorhersage-/Projektionsanalyse zu verstehen, wie Sie ein bestimmtes Ergebnis erreichen (oder verhindern) können.

Es hilft bei der Beantwortung von Fragen wie:

- Wie stark kann der Umsatz steigen, bevor es zu Lieferengpässen kommt?

- Wie schnell wird mein Rückstand wachsen, wenn wir weiterhin unterbesetzt sind?

Ursachenanalyse

Schließlich hilft die Ursachenanalyse dabei, die Herausforderungen des aktuellen Prozesses zu verstehen. Dies ist besonders leistungsfähig, wenn es mit einer anderen Technologie, Prozess-Mining, kombiniert wird, um die reichhaltigsten Erkenntnisse zu gewinnen.

Es hilft bei der Beantwortung von Fragen wie:

- Ist dieser Engpass auf unausgewogene Teams oder auf Ressourcenknappheit zurückzuführen?

- Welche Schritte im Prozess führen dazu, dass er sich verlangsamt?

Blick unter die Haube

Sie fragen sich wahrscheinlich, wie das funktioniert. Es folgt ein paar einfache Schritte.

Zuerst erstellen Sie ein neues Vorgehensmodell (in der Regel BPMN) oder verwenden ein früheres Modell, das Sie bereits haben oder mit einem Partner erstellt haben. Anschließend konfigurieren Sie das Modell (z. B. wie lange dauert diese Aktivität? Wie hoch ist die Wahrscheinlichkeit, dass dies eintritt?). Process Mining kann hier besonders nützlich sein, um die Daten objektiv zu erheben.

Führen Sie es dann aus. Dies ist Ihre Baseline.

Ändern Sie dann die Parameter (z. B. fügen Sie eine Person hinzu, die Sie einstellen möchten)

Führen Sie es dann erneut aus. Ändern Sie dann die Parameter. Führen Sie es dann erneut aus… und so weiter und so fort.

Am Ende des Tages erhalten Sie einen Bericht über die vorgeschlagenen Optionen, die erforderlichen Investitionen und die Auswirkungen. Dies ist besonders hilfreich, wenn Sie vor denjenigen präsentieren, die Ihnen Budget zur Verfügung stellen können.

Auswahl des richtigen Simulationsanbieters

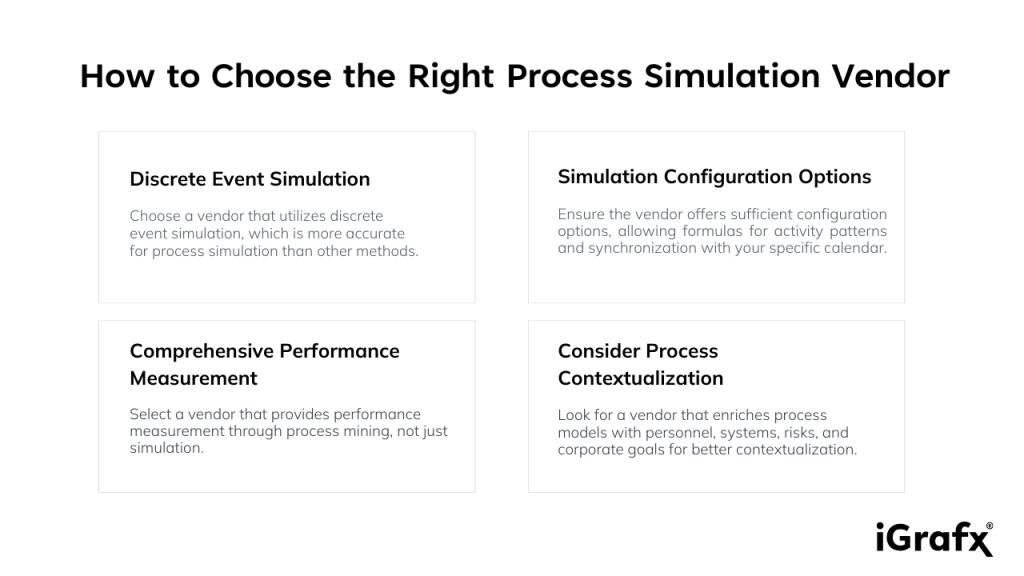

Sie fragen sich wahrscheinlich, wie Sie den richtigen Anbieter für Prozesssimulationen auswählen, um loszulegen. Es gibt ein paar Überlegungen, die Sie beachten sollten.

Insbesondere für die Prozesssimulation und andere Arten von Simulationen, die Zeitreihendaten beinhalten, sollten Sie einen Simulationsanbieter wählen, der ereignisdiskrete Simulationen verwendet. Sie ist dafür wesentlich genauer als andere Simulationsmethoden wie Monte Carlo.

Außerdem sollten Sie sicherstellen, dass die Konfigurationsoptionen für die Simulation für Ihre Anforderungen ausreichend sind. Erlaubt Ihnen der Anbieter, Formeln zu verwenden, um verschiedene Aktivitätsmuster zu beschreiben (Umsatzsteigerung um den Black Friday herum) und können Sie mit Ihrem spezifischen Kalender synchronisieren (regionale Feiertage, verschiedene Schichten und Überstunden)?

Und schließlich benötigen Sie einen Anbieter von Prozesssimulationen, der über die Simulation selbst hinausgehen kann. Sowohl durch die Messung der Leistung durch Process Mining als auch durch die Kontextualisierung der Prozesse, die Sie simulieren, und die Anreicherung der Prozessmodelle mit dem zugehörigen Personal, den Systemen, der Dokumentation, den Risiken und den Unternehmenszielen, auf die sie sich auswirken.